Home > Products > Stainless steel welding wire

ER308L Welding Wire

Stainless Steel Welding Wire

Standard: AWS A5.9/A5.9M:2006 An American National Standard.

YIETO manufactured in grades 307, 308, 308L, 308LSi, 308LMo, 309, 309L, 309LSi, 309LMo, 310, 312, 316, 316L, 316LSi, 317L, 318, 320, 321, 347, 347Si, 383, 385, 409, 409Nb, 410, 410NiMo, 420, 430, 439, 446LMo, 630, 630, 2209, 2553, 2594, 3556.

GMAW (MIG) - GAS METAL ARC WELDING WIRE

MIG wire bright drawn/ bright finish / soap drawn (de-coated) matte finish in precision layer wound spools .

Sizes (mm): 0.8, 1.0, 1.2, 1.6, 2.0.

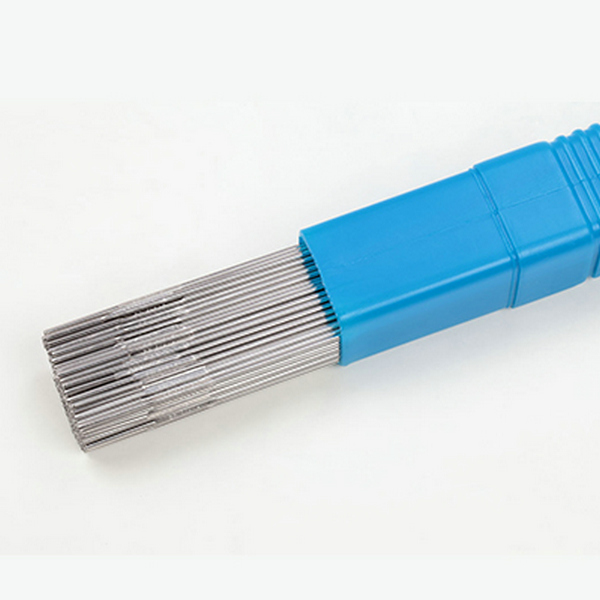

GTAW (TIG) - GAS TUNGSTEN INERT ARC WELDING WIRE

Tig Wire Bright Drawn Bright Finish in cut length 1000 mm, Grade is embossed on the head of wire.

Sizes (mm): 1.6, 2.0, 2.4, 3.2, 4.0.

SAW - SUBMERGED ARC WELDING WIRE

SAW wire bright drawn/ bright finish / soap drawn (de-coated) matte finish in precision layer wound spool

Sizes (mm): 1.2, 1.6, 2.0, 2.4, 3.2, 4.0.

CORE WIRE FOR WELDING ELECTRODE

Core wire is produce welding electrode, hot rolled & annealing & pickling finish.

Sizes (mm): 1.6 , 2.0, 2.4, 3.2, 4.0, 5.0.

Product Description

CLASSIFICATION : AWS/SFA-5.9: ER308L, BS 19.9.L

DIN 8556: WK. 1.4316

CHARACTERISTICS : ER308L is austenitic Stainless steel welding wire, the weld metal contains ferrite and resistance to crack is extremely good. Low carbon assists austenitic arc stability and improves corrosion resistance such as intergranuler type. The mechanical properties of the weld metal are good.

APPLICATION : ER 308L welding wire of low carbon 19%Cr-9%Ni steel for Automobiles and Chemical Industries such as oil, Medical, Fertilizer Textile and Railway Industries and For Nuclear reactors. Designed for welding SS 301, 302, 304, 304L, 308, 308L, 321 and 347 grades.

SHIELDING GAS : welding with 100% Ar gas Or Ar+2%O2 gas.

| C | Mn | Si | S | P | Ni |

| 0.030 max. | 1.00-2.50 | 0.30-0.65 | 0.030 Max | 0.030 Max | 9.00-11.00 |

| Cr | Mo | Cu | |||

| 19.50-22.00 | 0.75 max. | 0.75 Max |

| UTS (N/mm²) |

Proof strength (N/mm²) |

EL % (5d) | CHARPY “V” NOTCH IMPACT AT |

FERRITE Qty.(FN) |

| 520-660 | 360-450 | 35-45 | +20°C : 100-150 J -196°C : 50-70 J |

8-10 |

| Size(mm) | Size(inch) | Current Condition (DC+) | Voltage (V) | Gas Flow Rate L/min. | Spool packing 12.5 kg. | Spool packing 15 kg | Drum packing 100/200kg |

| 0.80 | 0.031 | 70-220 | 16-24 | 10-20 |  |

|

X |

| 1.20 | 0.047 | 150-300 | 24-34 | 15-25 |  |

|

|

| 1.60 | 1/16” | 150-350 | 28-36 | 15-30 |  |

|

|

| Size(mm) | Size(inch) | Length(mm) | Length (inch) | Current Condition(DC+) | Voltage(V) | Tube packing 5 kg | Box packing 20 kg |

| 1.60 | 1/ 16” | 1000 | 36” | 40-80 | 10-16 |  |

|

| 2.0 | 5/ 64” | 1000 | 36” | 50-100 | 12-18 |  |

|

| 2.4/ 2.5 | 3/ 32” | 1000 | 36” | 60-120 | 14-20 |  |

|

| 3.2 | 1/ 8” | 1000 | 36” | 100-150 | 16-24 |  |

|

| 4.0 | 5/ 32” | 1000 | 36” | 140-200 | 18-28 |  |

|

And also available RAAJMIGER308LSi version for MIG welding process

Customer packing on request.