Home > Products > Stainless steel welding wire

Stainless Steel Welding Wire

Stainless Steel Welding Wire

Product Description

MIG wires are produced in various types of spools as well as in drum packing for continuous welding. Venus also provides customized packing and packaging of MIG wires. Whatever the application, our Stainless Steel MIG Wires bear a stamp of authority in the industrial circle. Our wires are manufactured as per the specifications of the American Welding Society (AWS).

Our MIG WIRES are manufactured in SS grades 307Si, 308L, 308LSi, 309, 309L, 309LSi, 309LMo, 310, 312, 316L, 316LSi, 317L, 318Si, 321, 347, 347Si, 409, 409Cb, 409Ti, 410, 410NiMo, 420, 430, 430LNb, 904L, 2209, 2597, 630 and nickel grades , NiCr-3 & NiCrMo-3

with bright, matte or semi bright finishes. Our stainless steel MIG wires are manufactured in sizes ranging from 0.60 mm to 1.60 mm diameter.

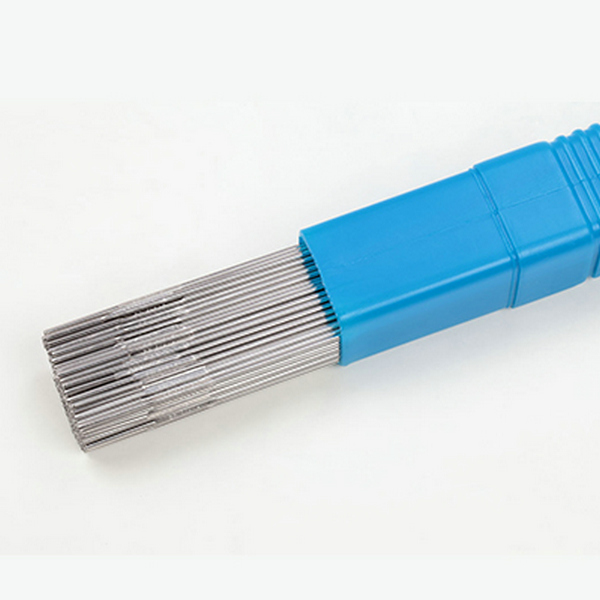

Gas Tungsten Arc Welding (GTAW) or otherwise referred to as Tungsten Inert Gas (TIG) welding has versatile applications and produces weld quality of high standards. In fact, a precise job can be easily carried out by a skilled welder with the help of a TIG welding machine.

Venus provides customized packing and packaging of TIG wires. Our Stainless Steel TIG Welding Wires have been the most preferred material for SS TIG welders. Our wires strictly conform to the standards and specifications of the American Welding Society (AWS). They are manufactured in the SS grades AISI 307, 307Si, 308, 308H, 308L, 308LSi, 309, 309L, 309LSi, 309LMo, 310, 312, 316, 316H, 316L, 316LSi, 317, 317Si, 318Si, 321, 347, 347Si, 409, 409Cb, 409Ti, 410, 410NiMo, 420, 430, 430LNb, 904 L& 2209.

To cater to the varied requirements and demands of TIG welding, Stainless Steel TIG Welding Wires ranging from 0.80 mm to 6.00 mm diameter are manufactured by us.

Grade and size are embossed on both ends for diameters 1.60 mm (1/16”) and above. Customized embossing such as heat number, brand name and batch number etc is available on demand.

Submerged arc welding is the most preferred mode of welding for long Straight Seams, Shipbuilding Industries, Oil & Gas Refineries, Fabrication of LPG Cylinders, Bridge Girders & Rotated Pipes or Vessels.

Venus produces excellent Sub Arc Weld Wires for the enhanced performance of continuous arc welding. Precision diameter tolerance of our wires makes the job easy for an arc welder. Our SS wires offer superior weld quality and fully comply with the specifications of the American Welding Society (AWS).

The welding wires manufactured by us are suitable for both automatic submerged arc welding machines and hand operated SAW guns. Our welding wires are manufactured for SS grades AISI 307, 307Si, 308, 308H, 308L, 308LSi, 309, 309L, 309LSi, 309LMo, 310, 312, 316, 316H, 316L, 316LSi, 317, 317Si, 318Si, 321, 347, 347Si, 409, 409Cb, 409Ti, 410, 410NiMo, 420, 430, 430LNb, 904L & 2209.

Venus guarantees that SAW SS wires developed by them will provide yields and deliver the most advanced and productive welding products.